PMB Presses

Our customers have chosen a PMB press because:

- Probably the world’s most reliable press.

- They are dimensioned for +30 years of production.

- Spare parts are delivered quickly, as all wearing parts are from PMB’s warehouse.

- Quick help in the event of a downtime, from locally employed technicians throughout Denmark.

- PMB has 90 years of experience in the development, repair, service and maintenance of presses.

What is a H-press?

What is a C-press?

A c-press is characterized by the press stand is shaped like a “C”. The press is used to punch, lure, cut, or bend various items. The C-press is often used for manual production of small series, or in productions where the workpieces are too complicated to produce in an automatic press line. The press can also be used as a cheaper alternative to a four-stand press in an automatic press line.

Why are PMB presses so robust?

- Compared to other manufacturers

Many press manufacturers today manufacture presses exclusively from welded steel racks, optimized for strength rather than stiffness, using the FEM analysis. This is to be able to manufacture presses as cheaply as possible.

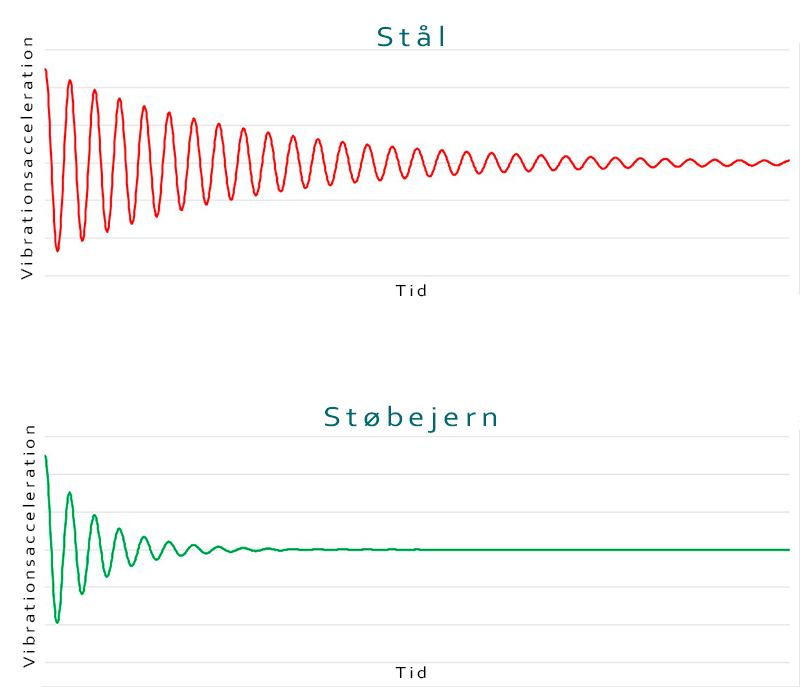

PMB has stuck to its traditions, where we don’t compromise our quality and safety. The presses are cast in ductile iron, which is a special vibration-damping cast iron. The graph shows how fast the cast iron absorbs the vibrations compared to steel. In fact, cast iron is 10 times more vibration damping than steel. The cast iron combined with a relatively high mass, makes a PMB press one of the most robust on the market.

The advantages of a molded press:

- The many parts and components of the press have a longer lifespan.

- Less downtime on the press, which will result in a more stable production.

- Cutting and punching tools have a longer service life due to the less vibration. Tools do not need to be sharpened as often.

Which press should you choose?

EPF, EPK, KLH, KDH

The C-press is available in two different types: EPF and EPK. The difference between the two types is that the EPF has the crankshaft lying alongside the length of the press, ie. the fly wheel sits on the back side of the press, and on the EPK the crankshaft lies across the press, and the fly wheel thus sits on the side of the press. The EPK type bends less as the crankshaft is supported on both sides of the connecting rod.

The H-press is also available in two editions: KLH and KDH. The difference between the two types is that KLH has one connecting rod and KDH has two connecting rods because it has a wider table. Both are similar to the EPK transverse crankshaft, but on a H-press, the crosshead is supported in all four corners. Together, this provides a more stable machine that protects the tools and provides virtually no deflection.

Ordinary or gear power press

Almost all PMBs C-presses are also available in a geared version, also called a gear power press. The purpose is to achieve a greater work performance for the press. This is because it is not sufficient to choose a press based on its pressing power alone. It’s crucial to also consider the required energy that the press must provide. Gear power presses are tagged with a ‘T’ in the type, e.g. the EPF will be called the EPTF.

Summary

EPF

- Good ‘all around’ press for most tasks.

- Crankshaft supported on one side of the connecting rod.

- Affordable.

EPK

- The crankshaft is supported on both sides of the connecting rod.

- Less deflection.

- Good for more critical tasks.

H-stand

- The crankshaft is supported on both sides of the connecting rod.

- The ram is guided in all 4 corners.

- Virtually no deflection.

- Perfect for critical tasks.

Gear power presses

- Named EPTF and EPTK.

- Higher work performance.

- Suitable for punching and cutting in very thick plates.

"Know your eccentric press"

Kurt A. Olsen's book

PMB has always taken great pride in sharing our specialist knowledge with like-minded people. This is always based on our solid knowledge, which we have built up throughout many years of experience. Therefore, it is important for us to share the available professional knowledge we have.

“Know Your Eccentric Press” is a book about the structure, dimensioning and correct use of the eccentric press. The book is written by Kurt A. Olsen, whose knowledge of eccentric presses is attributed to his work as a former technical manager at Povl Møllers Maskinfabrik A/S. The book informs about eccentric presses in general but is based on PMB’s self-produced presses.

This book is primarily aimed at eccentric press users with the most basic knowledge of the operation and use of the eccentric press.

The purpose of the book is to provide a greater knowledge of the theory and dimensioning of the eccentric press. Of which to convey all the practical functions of an eccentric press and how to use it properly. Furthermore, the book is intended to provide practical information and instructions that can be used in everyday life.

Therefore, at the back of the book there is a collection of:

- Diagrams

- Tables

- A collection of formulas that can be used as a reference work.

As well in the penultimate section of the book, you can find the most important peripheral equipment for interconnection with an eccentric press – also here with good advice and instructions.

You can click here to open the book in PDF format. Or click on the image.

The book's theory and empiricism

A large part of the book’s theory is taken and edited from Sv. E. Pedersen’s legacy. Sv. E. Pedersen was CEO of PMB from 1952 to 1985. He was one of Denmark’s (very few) experts on eccentric presses and left a lot of written material regarding the theory and dimensioning of eccentric presses.

PMB timeline with presses

Since the 1930s, has Povl Møller (PMB) produced almost 7,000 C-presses.

PMB acquired Dansk Pressefabrik (DPF) in 1978, which also produced C-presses and H-presses. PMB has since taken the H-presses into the range. PMB has produced H-presses from 40 tons to 300 tons capacity.

We have 100 years of experience and made PMB’s C-presses one of the most robust and reliable eccentric presses on the market. At the same time with its timeless design, it stands razor sharp at the many factories around Europe. It’s a press built to run production for decades.

Do you have any questions or other inquiries?

You are more than welcome to contact us, with your question, search for advice and guidance or anything else.

We really want to help you and are always available!