Embossing

Embossing is a process that covers a wide range of chipless forming.

Examples include cold and hot forging, drop forging, calibration, plane leveling, prism leveling, embossing of beads, knobs, and recesses, and embossing of patterns and text.

An example of the latter is the embossing of coins. As for cold and hot forging, drop forging and calibration, it is a specialty that entire textbooks can be – and have been – written about. The ordinary eccentric press user usually only experiences plane leveling, embossing of beads, knobs, and recesses, and embossing of patterns and text.

One should never omit the embossing operation when calculating pressure and work requirements as the embossing operation may require quite large pressure requirements and, with deep embossing operations, quite a large work requirement.

We do not perform embossing at Povl Møllers Maskinfabrik, but our customers use our machines to emboss metal. This could be, for example, a logo or a brand in a specific contour or shape in a metal plate, which requires press force.

Calculation of press force requirement and work in embossing

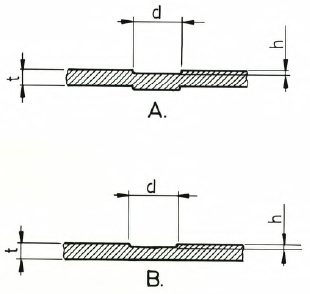

To calculate the press force for an embossing we must first and foremost get hold of the embossed cross-section. Depending on the appearance of the embossing there are two ways to find this, whether it is a full embossing or a partial embossing. The difference can be illustrated by the following example.

Here is a partial emboss (A) and a full emboss (B). The difference lies in that more material needs to be moved in case B than in case A.

The emboss cross-section in case A is calculated as the circumference of the emboss times the plate thickness, and for a circular emboss, it becomes:

\[O_{partial\ emboss} = \pi \cdot d \cdot t\]

Where it is mainly the “bait piece” that needs to be moved, where d is the diameter of the emboss and t is the plate thickness.

In case B, we need to move all the material in the entire emboss area out to the surroundings, so the emboss cross-section for a circular emboss in this case is equal to the area:

\[O_{full\ emboss} = \frac{\pi}{4} \cdot d^{2}\]

The necessary press force for the embossing is then:

\[P = R_{0,2} \cdot O\]

Where R_0.2 is the yield strength of the material and O is the embossed cross-section.

The necessary work for the embossing is found using the usual formula for work, which is force times path length:

\[W_{emboss} = P \cdot h\]

Work is often the parameter that most people overlook when calculating whether the press is suitable for producing their items, but this is a big mistake. If it requires more energy to produce the item than the motor can supply to the flywheel before the next press stroke, the flywheel will stall.

Calculation example for partial embossing

Assuming you want to create a circular partial emboss with a ø15 mm piston 0.3 mm deep in a 2 mm plate, which has a yield strength of 280 N/mm2, the press force and work are calculated as follows:

First, the embossed cross-section is found:

\[O = \pi \cdot d \cdot t = \pi \cdot 15\ mm \cdot 2\ mm = 94,2\ mm^{2}\]

The press force thus becomes:

\[P = R_{0,2} \cdot O = 280\frac{N}{mm^{2}} \cdot 94,2\ mm^{2} = 26.376\ N \approx 26,4\ kN\]

The necessary work requirement to perform the embossing is then:

\[W_{emboss} = P \cdot h = 26,4\ kN \cdot 0,3\ mm = 7,92\ J\]

To create this emboss, a press force of 26.4 kN (2.7 tons) and just under 8 J of work is required.

Do you have any questions or other inquiries?

You are more than welcome to contact us, with your question, search for advice and guidance or anything else.

We really want to help you and are always available!