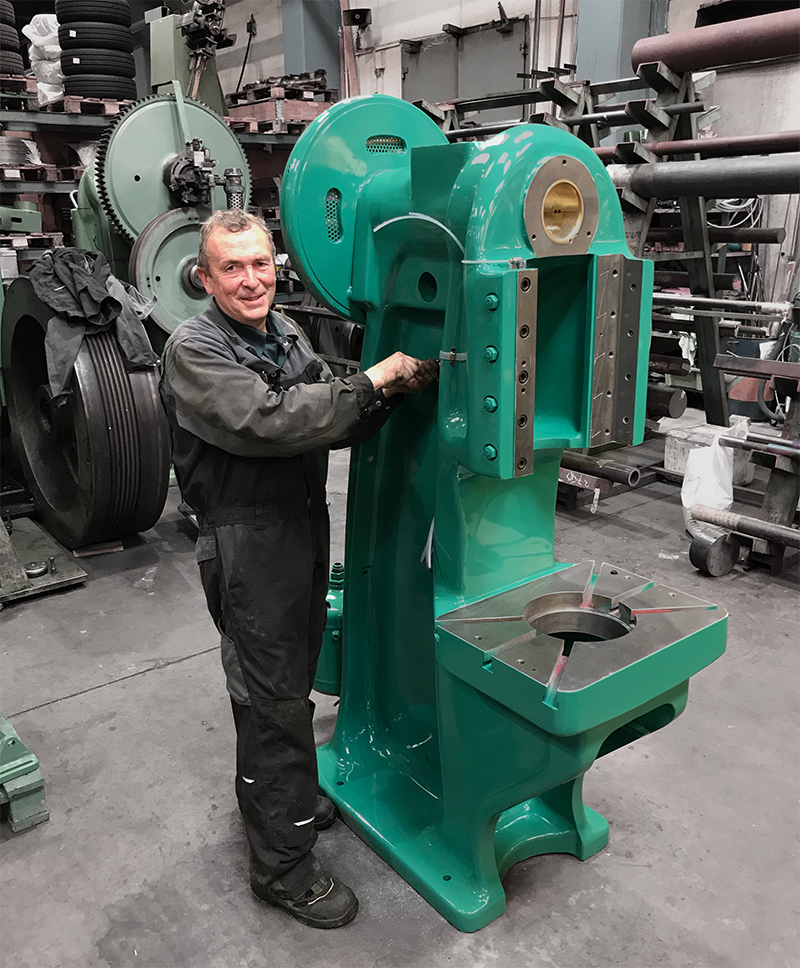

Press service

PMB service

PMB does press service and inspection of your presses. We specialize in several machines and take care of many different tasks.

PMB’s experienced service technicians live in Zealand, Funen and Jutland. The cars have the most common spare parts. If your press has broken down, PMB’s service personnel can in most cases get it up and running the same day.

PMB’s technicians visit our customers in Norway, Sweden, Finland, France, Poland and Lithuania, or wherever our customers may be.

Good reasons to have its presses (and other machines) inspected

- Employee safety

- Operational safety

- Minimize the cost of major repairs

- Compliance with regulatory requirements and manufacturer’s recommendations

We are specialists

We specialize in several machines, and we really want to help you! PMB’s technicians perform statutory inspections on:

- Eccentric presses

- Hydraulic presses

- Spindle presses

- Edge presses/edge bends

- Saxony

- Lifting tables

- Performances

- Settlers/straighteners

- As well as other sheet metal working machines

The tasks we take care of

- Repairs

- The statutory inspections

- Stop time measurement

- Crack test

- 5 year inspection

- Upgrading of control units and running-in

- Installation of conveying equipment and other equipment

- Dimensioning and establishment of entire press lines

Service Requirements

Statutory inspection in accordance with the Machinery Directive

PMB reviews the entire press and its management in accordance with PMB’s service list, which is handed out as documentation after completion of the review. Any repairs and replacements are agreed before they are carried out.

If the press is operated by hand, it is classified as an annex 4 machine, ie. a particularly dangerous machine. Therefore, an increased service frequency may become necessary. Eg. if the press is used 8 hours per day it must be inspected 4 times a year.

Read the rules here (page 28) (opens on new page)

Definition of Annex IV machines (page 377, item 9) (opens on new page)

Stop time measurement

If the press is running by hand, there must be a stop time measurement once per year. The measurement is made to ensure that the press works optimally and is able to stop immediately, if a dangerous situation is about to occur and the emergency stop is pushed. In addition, it may be necessary to check the stop time when there are light grids around the dangerous movements.

The measurement may indicate that a brake is wearing out or has been filled with oil.

Calculation of the measurement is defined in the Standard for Mechanical Presses. DS/EN 692+A1: 2009

(The above is valid until Harmonization of DS/EN ISO 16092-2: 2020)

Crack test

If the press is of the EPF type, ie. with a shaft end towards the user, and runs with manual loading, it must have performed a crack test once per. year. The test must show that the shaft is free of cracks which occur due to incorrect or excessive load on the press.

5-year inspection

PMB prescribes a 5-year inspection of the clutch/brake to be carried out. Clutch/brake is disassembled, cleaned and new seals and springs are mounted. For reasons of personal safety, this is an important inspection to comply with, because if the springs break, the press can no longer brake. The inspection also leads to increased operational reliability, as you reduce unforeseen breakdowns caused by the clutch. Furthermore, a mechanical inspection can be made, maintenance of bearings, shaft and ram guides are inspected for wear and defects. At KLH and KDH, the grease in the main bearings is also replaced.

Do you have any questions or other inquiries?

You are more than welcome to contact us, with your question, search for advice and guidance or anything else.

We really want to help you and are always available!